HEART – THE REALIZATION OF HUMAN AMBITION

See why Thunder at the Heart is at the core of all we do.

Grow your vision and potential beyond ambition into real solutions. Our expertise, our facilities and our innovations can help make the impossible possible.

GM’s Mission: Our goal is to deliver world-class experiences at every touchpoint and do so on a foundation of trust and transparency.

GM’s Vision: Our vision is a world with zero crashes, zero emissions and zero congestion.

Our own ambition pushes us to offer some of the most advanced technology available today. Working with us as an Integrator means you’re collaborating with a team committed to understanding your vision and bringing it to life with the same precision we dedicate to all our GM innovations.

Accelerating an Equitable All-Electric Future

Our role in the world is vital — and anyone looking to join us in shaping a more sustainable future is welcome. By working toward our vision, GM and GM Powered Solutions have made incredible progress. Learn more about GM Sustainability and GM’s environmental commitment below.

Collaborating with GM, Strength in Integration

Well beyond the open road, General Motors is central to the work and play that defines our existence. With every generation, our solutions change with the times — but they always evolve to amplify the drive within us all, pushing human ambition from background to close-up.

Electric and Autonomous Vehicle Revolution

For the first time, GM’s investment of $35 billion in EV and AV product development and the new Factory ZERO exceeds its gas and diesel investments.

Advancing Marine and Watersport Propulsion

GM has offered marine powertrain solutions for over 50 years but didn’t stop there — GM has provided innovations such as Direct Injection and Variable Valve Timing to help optimize the overall performance of watercraft.

Versatility Across

Applications

GM Powered Solutions can work with a variety of engines and fuel types across a range of applications — from emergency generators to industrial applications, we’ve taken engines beyond the road.

The Heart of Innovation

GM Powered Solutions is home to over 450,000 square feet of testing facilities and 120 testing cells — positioning us on the front lines of innovation.

Over 100 Years of Powertrain Solutions

GM has pioneered powertrain advancements — from replacing hand cranks with self-starting motors to shaping the future with advanced propulsion technologies today.

WE IMAGINE THE FUTURE AND THEN

PROVE IT CAN WORK

-

Dynamic Simulator Test

To ensure we deliver high-performance solutions — we simulate starvation in the oiling system during a vehicle's high-speed coring and off-camber operations by applying up to 53 degrees of articulation in any direction — to ensure tested vehicles perform as expected in the most brutal conditions.

-

-40 Degrees Cold Cell Test

We expect our advanced propulsion technologies to work in the harshest environments so we test all of our engines’ ability to start and continue to perform at the most frigid temperatures.

-

High-speed/High Load Test

As elegant as our advanced propulsion technology is, we expected it to be worked and run hard – so we stress test every component to ensure it will perform above and beyond expectations.

-

Severe Thermal Cycle Test

To go the extra mile, we ensure all components in our advanced propulsion technology will perform the same in extreme and rapidly changing temperatures.

Featured GM Powered Solutions Facilities

PONTIAC

Our Pontiac, Michigan, development and testing facility is the flagship of our eight global powertrain engineering centers. It features a 450,000-square-foot testing facility dedicated to developing engines and transmissions contained within millions of vehicles we drive.

With 120 testing cells, our proven lineup of engines and transmission products is put through a rigorous series of tests to ensure our products can withstand the punishment of real-world use and then some.

CHESTERFIELD

The Chesterfield, Michigan, engineering facility features dedicated engineers working to further the development of new technologies and GM engines for Marine, Industrial, On-Road and Off-Road applications.

TIMELINE

A Century of Experience is Only the Start

GM has been helping to power the machines that shape our world for over a century — and this continues to endure today, with GM engines powering delivery trucks to agriculture watering systems to recreational vehicles.

GM Powered Solutions only took its name in the last few years, but its origins trace back through GM Powertrain and beyond as a team of innovators that furthered GM’s Mission and Vision by engineering cutting-edge powertrain solutions.

1904–1909: Formation of GM

GM traces its origins back to William Durant first taking leadership over the Buick Motor Company, which developed engines for industrial and marine use. From there, GM integrated the best minds and innovations under its name — including Cadillac, Olds Motor Works (later Oldsmobile), Elmore Welch, Cartercar, Oakland (later Pontiac), Reliance Motor Truck Company and the Rapid Motor Vehicle Company (later GMC) – into one automotive superpower.

1941–1945: WWII

When America became involved in WWII, every GM division dedicated to the effort. GM built more than 198,000 diesel engines, 206,000 aviation engines, and thousands of other gasoline and marine engines for the armed forces’ use during WWII. In this time, GM divisions further innovated propulsion technology for heavy marine and submarines, heavy-duty trucks, tanks and landing crafts.

1964: Electrovair

After Chevrolet began building and marketing engines for automotive, agriculture, industrial and marine sectors in 1963, the Electrovair I and Electrovair II were developed to test the viability of electric power for passenger cars. A new electric system replaced the engine and transmission, and R&D helped develop the 450— and 530—volt silver-zinc battery packs – advancing electric vehicles with a top speed of 80 mph and a range of 40—80 miles per charge.

1971: Electric Lunar Rovers

In 1964, GM worked within the aviation industry to develop and manufacture the EV mobility system for the first Lunar Roving Vehicle taken to the moon in 1971. GM led efforts in furnishing the vehicles with wheels, suspension and motors. Today, you can still see the Lunar Roving Vehicles from Apollo missions 15, 16 and 17 on the moon.

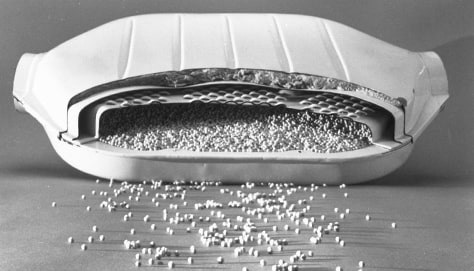

1974: First Catalytic Converter

GM R&D played a pivotal role in developing material innovations and catalyst technologies and led to GM R&D, becoming one of the first groups to predict the correlation between atmospheric pollution and the earth’s surface temperature.

From 1975 on, all GM cars sold in the U.S. and Canada were equipped with the catalytic converter, and GM made its technology available to the rest of the industry at no cost.

1979–1989: Electric Vehicle Conversion

GM collaborated with the U.S. Department of Energy to convert 35 GMC full-size vans to electric power, 15 of which were used within the communications industry in Detroit. Between 1985 and 1989, GM furthered the electric vehicle movement by building 100 more GMC van conversions for an Electric Power Research Institute program, utilizing experience gained from the earlier program.

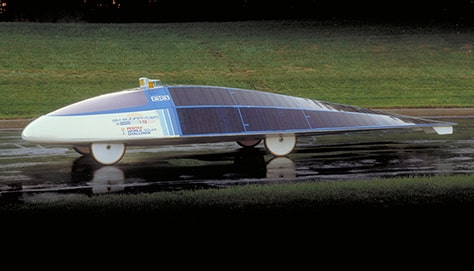

1987: Sunraycer

GM designed and built the Sunraycer as a solar-powered race car for the inaugural solar-powered vehicle competition, the 1,950-mile (3,138-kilometer) World Solar Challenge race. The race car’s innovative power came from a brand-new electric motor based on Magnequench permanent magnets developed at GM's R&D and won the first race in 1987 by a huge margin, further propelling GM toward an electric future.

2002: VORTEC Industrial Engines

GM Powered Solutions manufactures and sells its Vortec industrial engines to numerous original equipment manufacturers, many of which are designed to operate on multiple fuels, including gasoline, liquid propane gas and natural gas. The introduction of Vortec's innovations ushered in higher performance and efficiency engines to a wide range of applications outside of just on-road vehicles.

2005: 1st Fuel Cell Military Truck

Through R&D efforts beginning in 2005, GM unveiled a fleet of 16 Equinox-based hydrogen fuel cell concept vehicles and developed the fuel cell-powered Chevrolet Colorado pickup and the Colorado ZH2. GM tested these new fuel cell-powered concept vehicles in extreme field conditions to confirm the viability of hydrogen-powered concept vehicles on military missions — advancing fuel cell technology for new challenges.

2009: DURAMAX Diesel Gears Up

GM Powered Solutions and GM geared up Duramax® Diesel engines for industrial applications in 2009. The Duramax Diesel had been recognized for operating quietness and smoothness, and its success in diesel vehicles proved to carry over into a wide range of industrial applications.

2010: Accelerating Zero Emissions

GM R&D developed groundbreaking methods that allow us to gauge the feasibility of implementing future vehicle technologies. As a result, GM began selling the Chevrolet Volt, a gas-electric plug-in hybrid vehicle and introduced electric networked vehicles. With these methods, GM accelerated its zero tailpipe emission vision.

2022: GM Ultium

Ultium, an electric vehicle battery and motor architecture designed by GM, promises to accelerate GM's vision of a world with zero emissions. With a modular, simplified design compared to fossil fuel engines, high-energy pouch cells can be arranged horizontally or vertically, in single layer or stacked configuration, Ultium delivers flexible engineering compatible with most vehicle designs. Soon, Ultium will deploy in EV vehicles across the GM portfolio and the EV industry.